I got this Pinto in Mid June 2011. I had it running and yard driving in just a week or so. The first thing I did was gut the inside. I removed everything I could without making it undrivable. I had just a small amount of floor rust to repair. I put the driver's seat in so I could move the car.

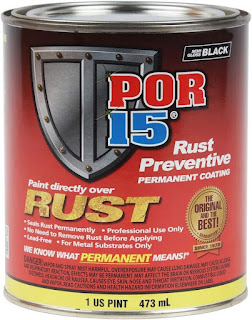

The rear passenger side under the back seat had some small holes just about 1/4 inch. At that time I had just learned about POR-15. I got a couple cans.

As you can see the passenger floor was in perfect shape. I scrubbed it clean and removed any surface rust.

Some of the floor looked perfect.

This looked a lot worse than it really was. I wire-brushed most of this rust off and treated it. No holes.

Those 1/4-inch holes got a bit bigger. I had to get creative on this repair.

This is behind the driver's seat, right-hand rear hole. I was going to just weld in a bit of sheet metal but there seemed to be flexing some so I added some angle iron for support.